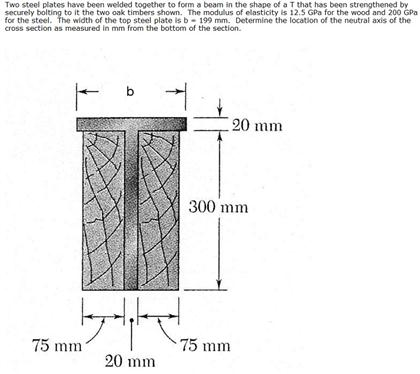

In this method a steel plate is sandwiched between two identical wooden beams and the beam and steel sandwich is bolted together.

Wooden beams and steel plates are securely bolted together to form.

The bending moment m 335 kip in and the moment of inertia 1104 2 in the maximum stress in the wood is steel marked out of 3 00 p flag question wood wood 10 in.

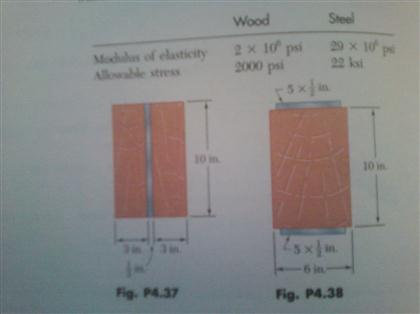

Using the data given below determine the largest permissible bending moment when the member is bent about a horizontal axis.

Modulus of elasticity of wood 14 gpa and for steel 200 gpa allowable stress of wood 14 mpa and for steel 150 mpa.

Half inch carriage bolts are spaced 16 inches apart with.

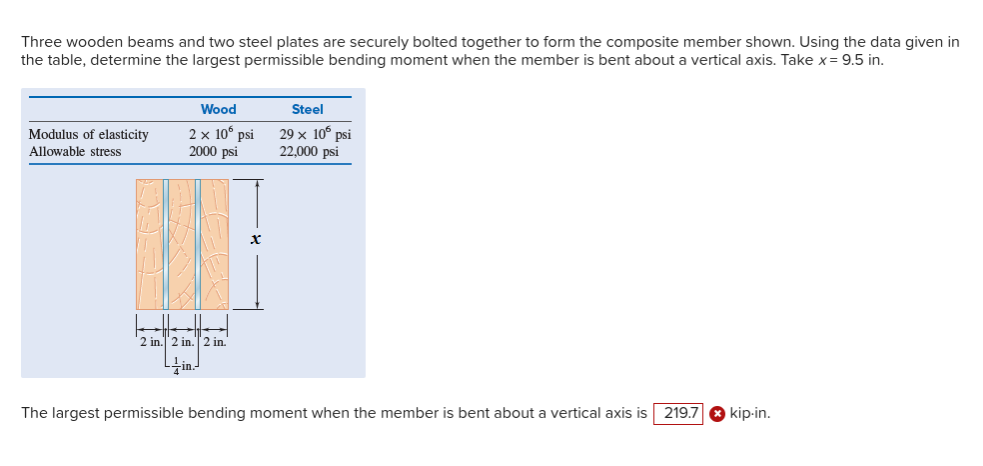

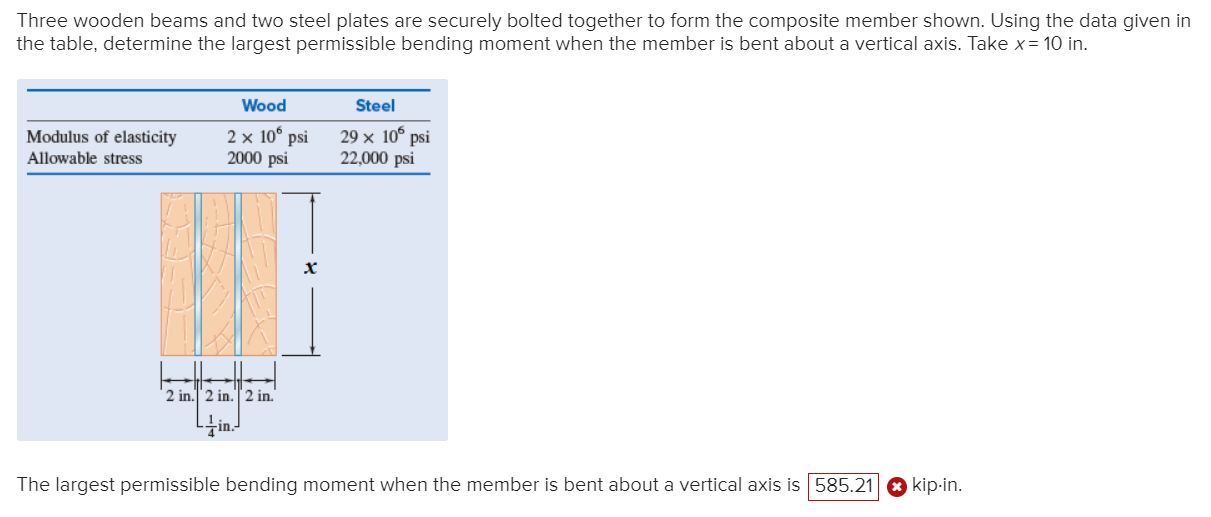

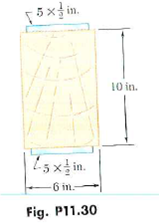

Three wooden beams and two steel plates are securely bolted together to form the composite member shown.

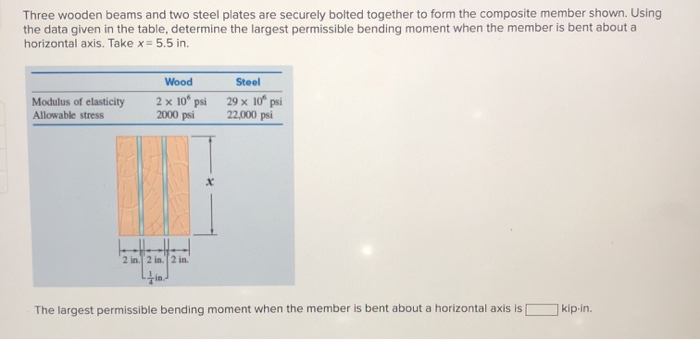

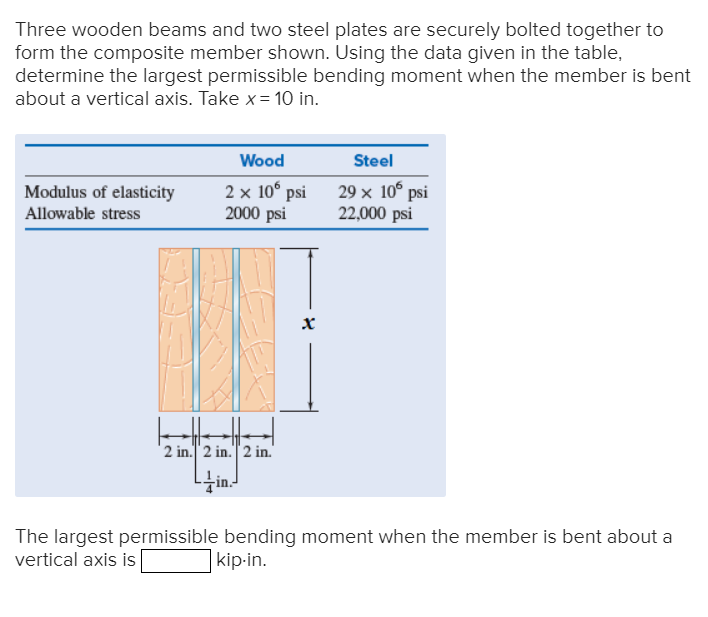

Three wooden beams and two steel plates are securely bolted together to form the composite member shown.

The bending moment m 335 kip in and the moment of inertia 1104 2 in the maximum stress in the wood is stpd wood wood 10 in 3 in 3 in in.

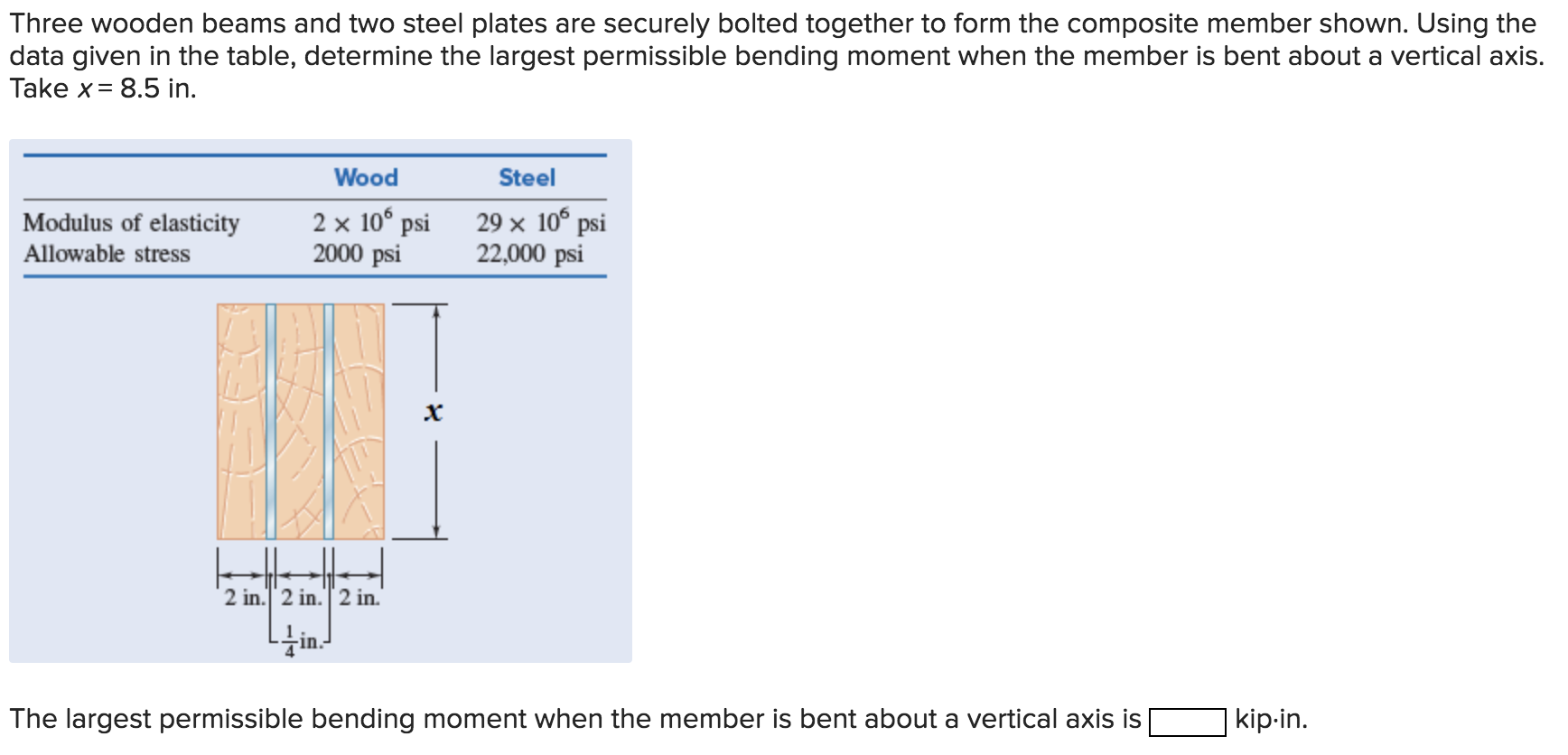

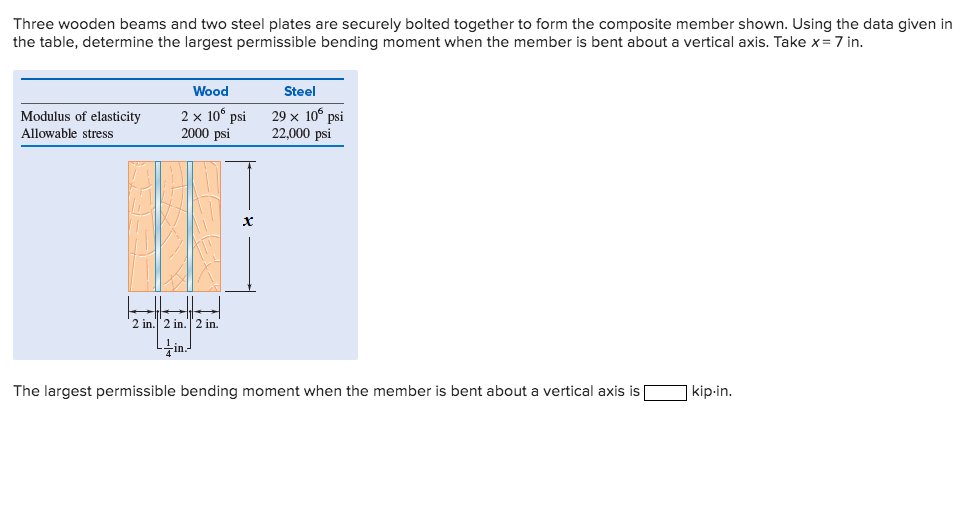

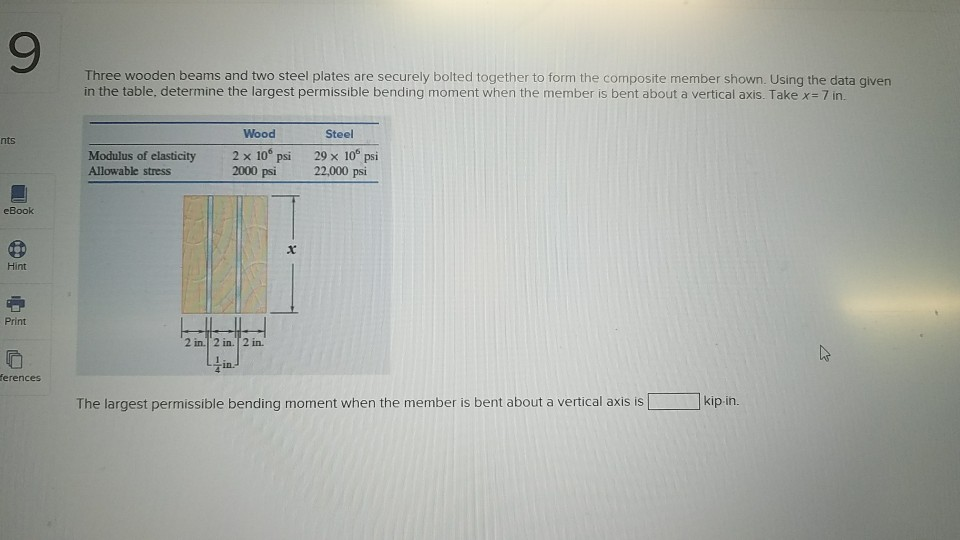

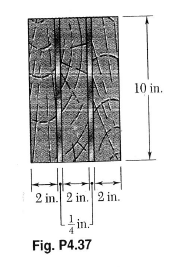

Using the data given in the table determine the largest permissible bending moment when the member is bent about a vertical axis.

Knowing that extol 29 10 psi and ewood 2 10 for wood.

Wooden beams and steel plates are securely bolted together to form the composite member shown.

Another way to reinforce a beam is with a flitch plate.

Wooden beams and steel plates are securely bolted together to form the composite member shown.

The steel plate should be as long as the beam with bolt holes punched or drilled through the steel.

Using the data given below determine the largest permissible bending moment when the member is bent about a horizontal axis.

Using the data given below determine the largest permissible bending moment when the member is bent about a horizontal axis.

Question 10 not yet answered wooden beams and steel plates are securely bolted together to form the composite member shown.

Three wooden beams and two steel plates are securely bolted together to form the composite member shown.

Knowing that esteel 29 106 psi and ewood 2 106 for wood.

Wooden beams and steel plates are securely bolted together to form the composite member shown.

Wood steel modulus of elasticity 2 x 10 psi 29 x 10 psi allowable stress 2000 psi 22 ksi.

Using the data given for wood and steel determine the largest permissible bending moment when the member is bent about a horizontal axis.

Typically the flitch beam is made up of a vertical steel plate sandwiched between two wood beams the three layers being held together with bolts in that common form it is sometimes referenced as a steel flitch beam.